What Does Motorcycle Parts New Zealand Specialists Do?

Table of Contents10 Easy Facts About Motorcycle Parts New Zealand Specialists ExplainedNot known Incorrect Statements About Motorcycle Parts New Zealand Specialists Some Known Incorrect Statements About Motorcycle Parts New Zealand Specialists The Ultimate Guide To Motorcycle Parts New Zealand SpecialistsHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.Motorcycle Parts New Zealand Specialists Fundamentals ExplainedMotorcycle Parts New Zealand Specialists for DummiesRumored Buzz on Motorcycle Parts New Zealand Specialists

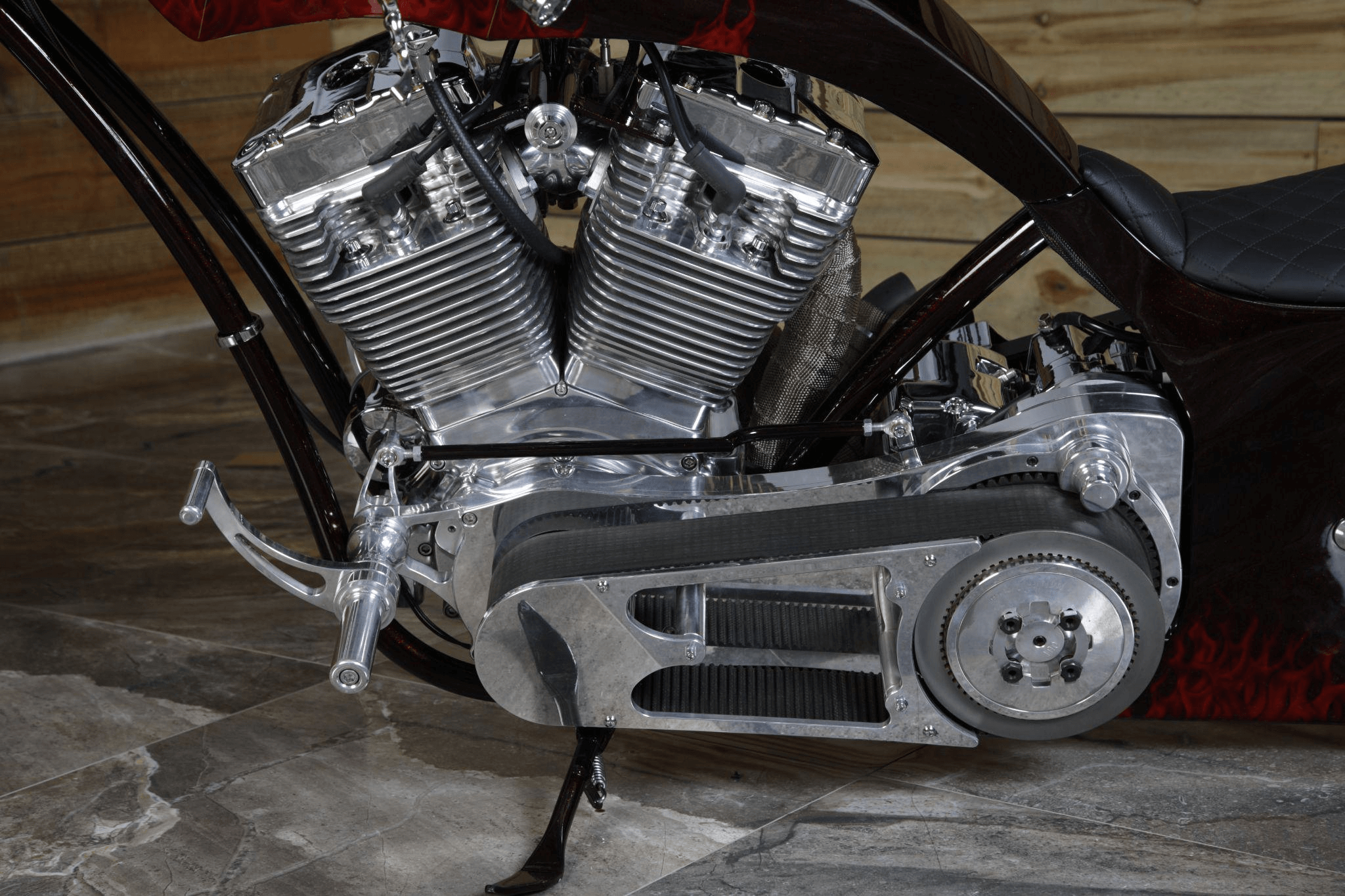

Get to out to one of our professionals today.CNC machining innovation is swiftly ending up being the prime focus of numerous various manufacturing processes around the world as a straight result of its many benefits over various other approaches. Furthermore, the markets that manufacture motorcycles have jumped on board with this fad. The most ingenious business are currently developing their engine parts and wheels using machining strategies initially established for motorbike components.

You may be wondering why we use. Now that we have your interest allow us describe the rationale behind this modern-day growth in the bike production sector.

The Main Principles Of Motorcycle Parts New Zealand Specialists

Additionally, you have complete control over the appearance of the elements, also down to the minute information. Occasionally, motorcyclists might choose to fix up their adventure by setting up aftermarket parts or changing the bike's makeover. Once more, computer system mathematical control (CNC) machining is one of the most sensible method. Upgrades may be of any form and style you want.

Not known Facts About Motorcycle Parts New Zealand Specialists

CNC machining might be made use of to make practically all of a motorbike's steel and plastic parts. To proceed, we'll go over a number of machined parts for motorbikes.

When customizing the wheels, the disks are where the focus ought to be. Most of them are constructed out of light weight aluminum. Aluminum alloys are widely known for the superior machining abilities that they possess. Milling treatments are made use of to acquire the preferred degree of wheel customization. Another facet of the motorcycle that may be individualized is the tires.

Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

When it pertains to a vehicle (or a motorcycle), the most important element is the engine. Several individuals suggest to it as the "heart" of the car. On the various other hand, the camshaft, the cylinder head, and the pistons have a tendency to be elaborate and require styles with a high degree of precision.

Usage just premium things, nevertheless, because these lights are crucial for the security of motorcyclists and other motorists or people on the roadway, particularly at evening. Motorbike headlights have 3 major components: the bulb, or light source, the lens, and the real estate.

Milling procedures with a remarkable finish would certainly result in the lenses having a reflective quality that is comparable to that of a mirror. The cover, on the various other hand, is not made up of fragile materials; instead, it is built out of difficult polymers that can be machined right into even more elaborate patterns.

Getting My Motorcycle Parts New Zealand Specialists To Work

Motorbike producers commonly cast these elements, but only for the production of bespoke parts. Machining on five axes in click here to find out more today's world is the ways by which any style form may be realized.

Choose Runsom for your tailored bike parts! We have the capacity to fabricate complex and stylish elements making your motorcycle incomparable.

Right here are a few examples of steels frequently made use of in motorcycle element machining. Light weight aluminum is the primary material utilized by business concentrating on producing customized motorbike elements to develop the majority of these components. In the past, we would certainly construct our engines out of actors iron. On the various other hand, aluminum is rapidly becoming the material of choice, partly due to the fact that it is a lot more light-weight.

Zinc refers to an additional steel that is extremely light in weight and has great machining high qualities due to its high mechanical strength. This material might be created right into virtually any form and keeps its measurements well. Also mission-critical parts that need a high degree of accuracy might benefit from their usage.

Motorcycle Parts New Zealand Specialists Things To Know Before You Get This

An additional metal that sees heavy use in the manufacturing of CNC-customized components is magnesium. It is among the lightest steels that are currently easily accessible and has excellent machinability functions and toughness appropriate with its reduced weight. Among the drawbacks of magnesium is that its dust might easily catch fire.

Their most common usage in generating different motorbike elements is bolts, such as screws and bolts. Their reduced sensitivity to oxidation and corrosion makes them ideal for this usage.

More About Motorcycle Parts New Zealand Specialists

It appears that CNC transforming and milling are the foundational processes. In addition, it needs maintaining bars of product, most usually plastic or steel, in setting and then turning a cutting device to get rid of areas of the product as the material is transformed.

These approaches are just as important and generate elements with high precision and regular quality. The processes assist boost the total high quality of the machined her explanation bike parts.

The Best Strategy To Use For Motorcycle Parts New Zealand Specialists